Advanced Scrubber Systems – Where Innovation Meets Compliance

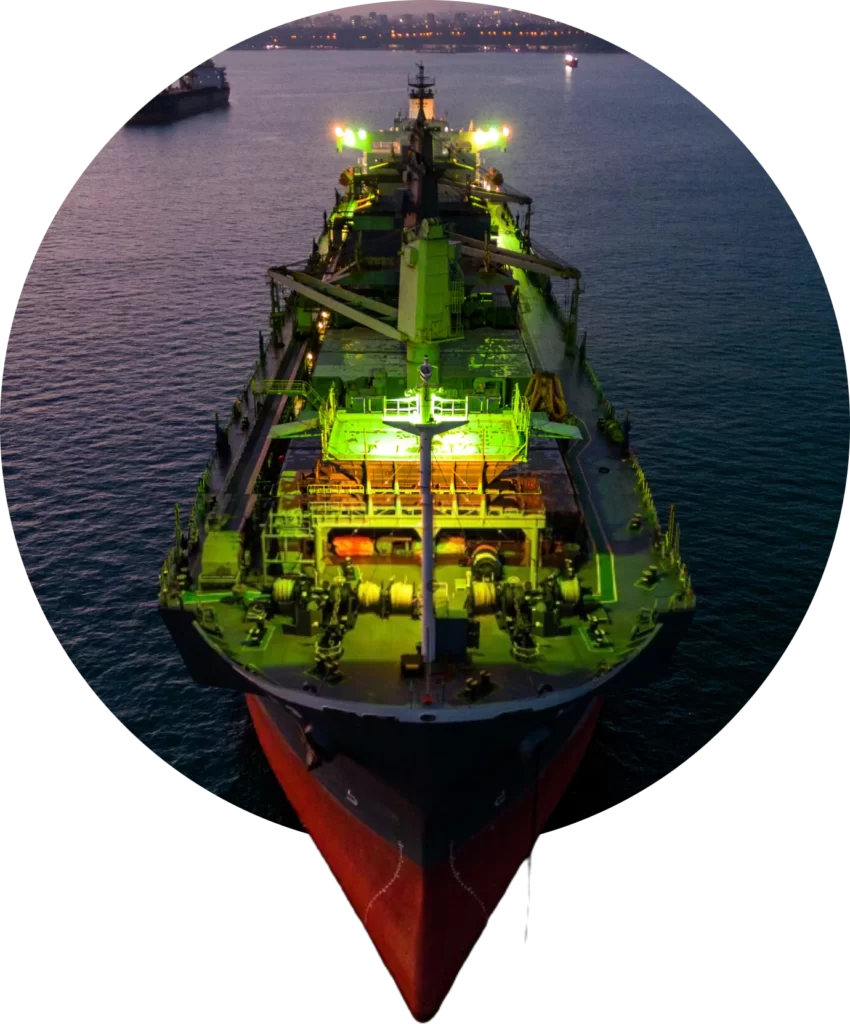

SOx Scrubbers for Ships and Cruises

Our advanced SOx scrubbers offer a proven solution for the treatment of exhaust gases in maritime transport. Adapted from effective land-based systems, our scrubbers meet the stringent requirements set by the International Maritime Organization regulations introduced in 2020.

Scrubber System

SOx scrubber for ship and cruises exhaust gases

A proven process adapted to maritime transport

A proven land-based solution brought to the sea

Scrubbers are responsible for the treatment of effluent gases and the perfect solution for the new requirements set by the International Maritime Organization regulations, which came into force in 2020. Srubbers act as a sodium-based dry scrubber to treat exhaust fumes from vessels running high sulfur diesel or heavy fuel oil engines.

A constant focus on sustainability

Delta Marine Scandinavia AB’s strategy revolves around sustainability and the dry scrubber is a truly sustainable solution that we are proud to have developed and promoted for the marine industry.

What can a Scrubber do for you?

Removal of up to 100 % of SOx and more.

Scrubber - Dry scrubber for ships and cruises

The Scrubber effluent gas treatment solution will help you achieve the desired SOx abatement levels. It also offers an unparalleled 99% particle clearance rate.

- A dry process for greater sustainability: With a Scrubber, no effluent is released into the sea and the waste is treated on land.

- A non-toxic product for added safety: The sodium bicarbonate-based sorbents used in our exhaust gas cleaning system are non-corrosive, non-irritating and non-toxic. As a result, they can be handled safely, which makes life easier for operators.

- Ease of installation, no dry-docking: dry scrubber installation is quick and does not require dry-docking. It also has important synergies with DeNOx Selective Catalytic Reduction.

- No large investment required: No energy is needed to pump the cleaning water. In addition, it is an adaptable solution that allows vessels to navigate in areas with different SOx regulations without having to change the type of fuel used.

How does our effluent gas treatment solution for ships work?

- Sodium bicarbonate-based sorbent is loaded onto the ship and stored on board in silos.

- When the vessel is in operation, the sorbent is injected into the vessel’s exhaust gas. The sodium sulfate residue resulting from the reaction with SOx in the exhaust gas leaks into the ship’s stack, along with other particulates, such as micropollutants, soot, etc.

- The residue is collected and stored in silos on board until it is disembarked for treatment on land.

Dry Scrubber and Wet Scrubber

What is the difference between a dry scrubber and a wet scrubber?

A “wet scrubber” is a process that uses seawater in a scrubbing tower to reduce pollutant emissions from a vessel. In this case, used water containing sulfates and other elements (metals, soot…) is either returned to the sea (in an “open loop” system) or stored on the ship (in a “closed loop”).

A dry scrubber, as its name suggests, does not use water. The dry system of our scrubbers is an effluent gas treatment solution that uses a sodium-based sorbent that removes up to 100% of SOx and more than 99% of particulate pollutants. No waste, debris or pollutants are discharged into the air or water due to the Scrubber’s onshore waste treatment process.

Why choose a dry cleaner?

- It offers a higher particle removal rate (greater than 99%) than a wet scrubber.

- Dry dock entry is not required for installation.

- It can be combined with DeNOx Selective Catalytic Reduction to achieve important synergies.

- Lower capital and operating expenses.

- Less chance of failure.

- Requires less maintenance and operation.

- It is safer, thanks to the non-toxicity of the sorbent.

- No effluents are released into the sea.

- The waste can be treated on land.